Events

Polysecure was present at the World's Leading Trade Fair for Water, Sewage, Waste and Raw Materials Management 2022 in Munich. It was a great event and platform for the circular economy. At the joint stand of the BDE, we were able to experience how many people, organizations and companies are working with energy and innovation to make the circular economy a success.

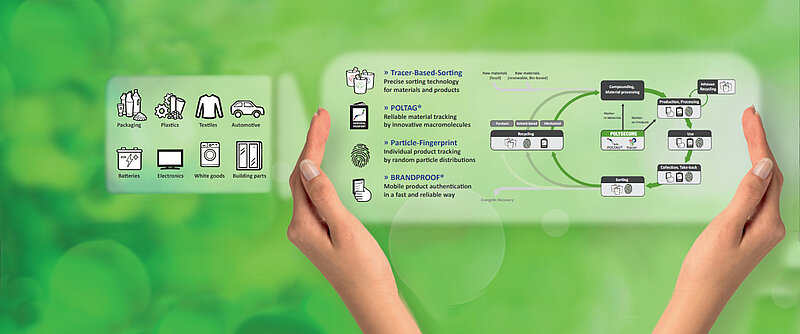

We take home with us that we are on the right track with our vision for a reliable, complete, technology-open and flexible sorting technology. It allows different waste streams to be sorted precisely and in the best possible way. Our technical solutions to promote the circular economy are based on efficient invisible marking, reliable detection and accurate sorting of materials and products. Feel free to form an impression of our economic and innovative sorting technology.

TECHNOLOGY PLATFORM

Our goal: Preserving resources & values

- Sorting waste streams completely and precisely according to definable fractions enabling high-quality recyclates and closed-loops in the most CO₂-efficient manner (Tracer-Based-Sorting-Technology – TBS)

- Individually tracking products to enable forgery-proof Digital Product Passports (DPP) with the same fluorescent particles as TBS (Particle-Fingerprint-Technology)

- Tracing materials to enable Dgital Material Passports (DMP) and e.g. monitor recycled content in products (POLTAG®-Technology)

TRACER-BASED-SORTING (TBS)

Solutions for high-quality sorting and recycling

Tracer-Based Sorting (TBS) is based on the use of our fluorescent particles. They are already integrated into or onto the object during production and invisibly indicate how the object is to be sorted and recycled at the end of life. In this way, the reliable sorting into definable, specific fractions according to the ideal recycling path is possible - a prerequisite for high-quality recyclates.

TBS-complete

Efficient open technology solution

With TBS-complete, we combine the detection of the tracer signal with further measurements (NIR, color, AI, opt. watermark). For this purpose, we are developing a combined detector together with Carl Zeiss AG, which for the first time enables a sorting process that is open to all technologies. Technically, all objects are singulated, detected and sorted innovatively in only one step - the result: maximum efficiency, flexibility and precision!

Wide Applicability

Wide applicability to all packaging formats and many other products. The tracers can be mixed in plastics or other materials or printed on packaging items or other products.

Sorting into definable, relevant fractions

The tracers are an additional sorting property and allow sorting into definable, relevant fractions enabling the production of high-quality recyclates and closed-loops. Examples for packaging are: differentiation of food/non-food, A-PET/PETg; identification of specific multilayers, brands or applications (e.g. coffee caps).

High Reliability

Within sorting, waste items move through a laser curtain exciting the tracers to emit their fluorescent sorting code equally in any direction. Detection is practically independent from deformation, position and movement of waste items.

High Purity of sorted fractions

The sorting code detection is distinct and very independent from the properties of waste items. Therefore practically no false positives and automatic separation of non-marked impurities and non-compliant materials -> solution to achieve “Tox-Free Environment”.

High Detection Rate

Laser excitation can be tuned for reliable tracer signals. Close to 100% of marked waste items are detected correctly.

Low Tracer Amounts

Low tracer amounts are sufficient. High chemical inertness, low solubility, high temperature stability provide good biocompatibility. Polysecure tracers have passed all toxicological and other tests for food contact approval.

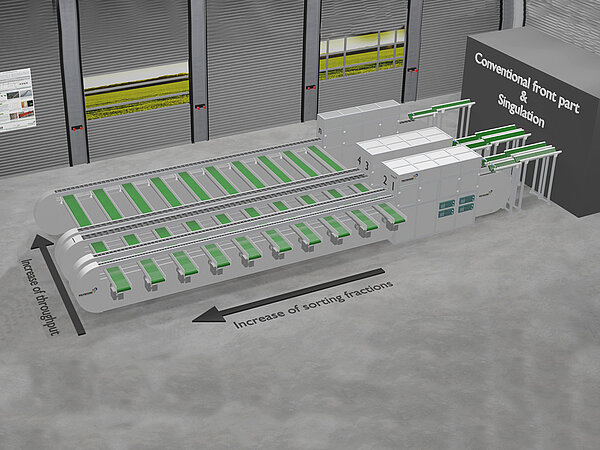

Precise Sorting in only one Step

With TBS-complete all waste items are singulated, detected and then sorted to their defined fraction in only one step and cost-efficient manner – comparable to letter sorting.

Scalable and Flexible

Single-line sorting. The sorting process is scalable, flexible and economical even with many fractions. Fractions for closed-loops, brands, better specified fractions can be added at marginal costs.

Best possible Identification Result

Combined detection of tracer, NIR, color, AI and optionally watermarks to create best possible, fast identification. Tracers are not needed per se, but a flexible tool to allow defined fractions, closed-loops and very high detection and purity rates.

Many Tracer Sorting Codes per Polymer

Tracer detection without background noise. Patented use of upconversion fluorescence allows many tracer sorting codes per polymer (~100) and very low tracer concentrations.

Future-oriented and Technology-open

Based on the new combined detector, TBS complete works with all current and potential future detection technologies and is thus technology-open. Always the right choice to apply the best possible detection process even in a dynamic technology landscape.

For a more circular and greener World

TBS-complete enables massive savings in primary material consumption and CO2 emissions.